uPVC advantages

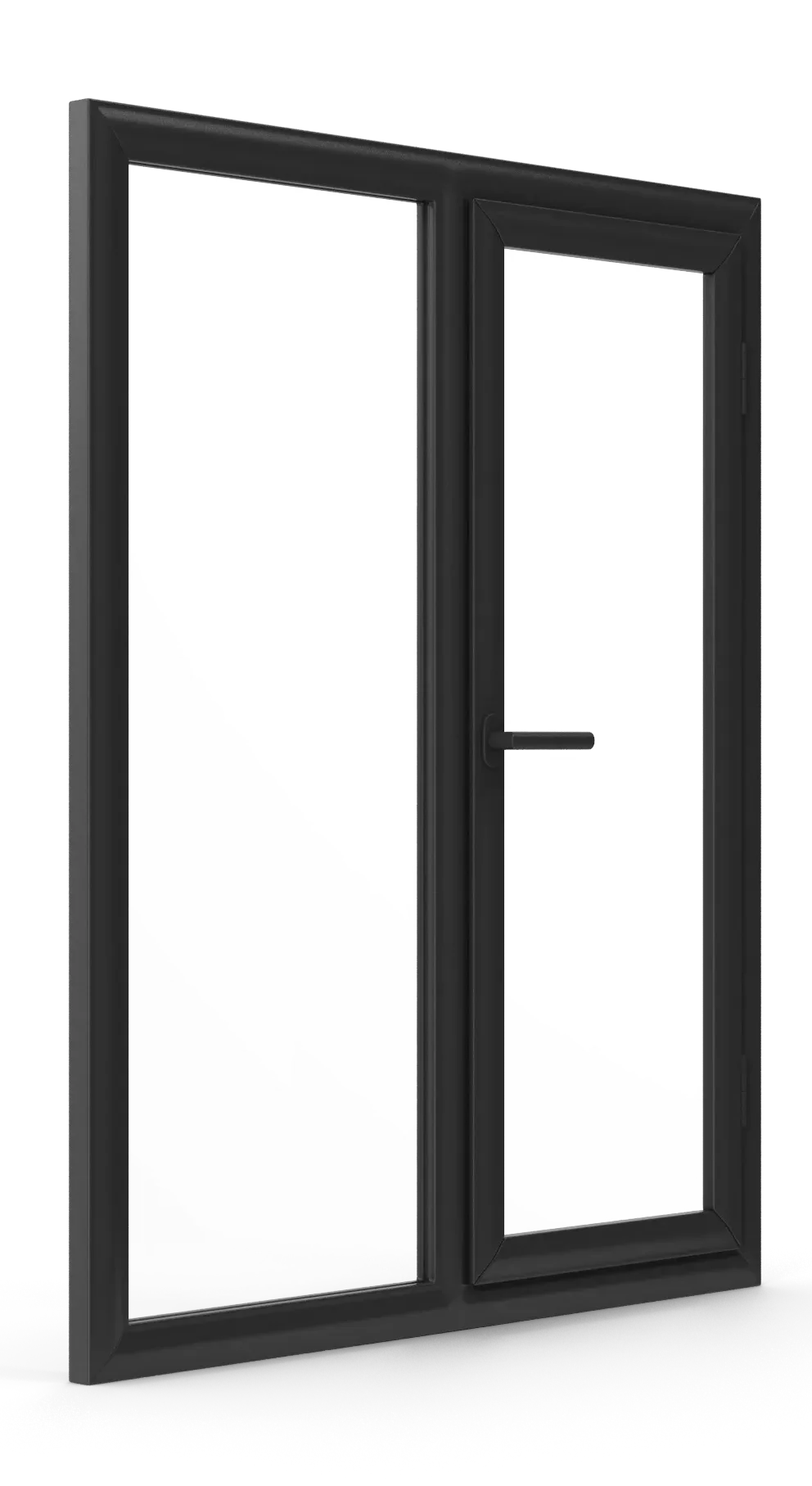

Unplasticized polyvinyl chloride (uPVC), also known as rigid PVC, is one of the most versatile and sustainable materials used in the construction industry. Polyvinyl chloride (PVC) has evolved over the years to become more efficient, durable, and affordable.

Since it is unplasticized, uPVC is more rigid and has efficient insulation properties. This makes it an ideal choice for windows and doors used for both commercial and residential purposes.

Unlike wood and aluminum, uPVC retains its shape in all weather conditions and remains unaffected by physical impacts. Its high-grade flexibility ensures long-lasting performance and minimal maintenance requirements.

Let’s first understand the

problem with other materials:

Wooden Windows

Wooden window frames may be a popular choice but they require high maintenance and proper care for longevity and durability.

- With deforestation being an alarming issue, wooden windows and doors pose a threat to the environment

- Wood is an organic and porous material, which means that it can quickly become susceptible to the elements

- Insect infestation: Wood windows are subject to rot or insect infestation if not properly maintained

- Wooden windows are prone to warping that often occurs from moisture and sunlight

- Wood shrinks and expands radically in response to humidity changes

- Wood is susceptible to damage or leaks

- There is a huge problem in waterproofing wooden windows

- Wood is costlier and requires more maintenance

Aluminum Windows

Aluminum windows are very light which makes them less desirable for ensuring security of your home.

- Aluminum doesn’t hold heat, therefore, not a good choice in colder climates

- It requires regular maintenance due to anodization

- Aluminum is prone to oxidation and is susceptible to corrosion especially if you live near coastal environments

- It is not energy efficient

- Due to lack of strength, aluminum cannot support very tall windows and doors

- Aluminum’s insulation properties are dependent on the glazing selected

- Aluminum can be water-stained easily

Steel Windows

Steel windows, although don’t require much maintenance but are very expensive and not suitable for all climatic conditions.

- Steel window frames are expensive and difficult to install when compared to other materials

- Steel window frames are not very energy efficient

- If you live in a coastal climate, steel windows and doors aren’t the best choice

PVC Windows

PVC, short for polyvinyl chloride, is a plastic, commonly used in construction. Due to its toxic nature, it is not ideal for home use.

- PVC windows are not very durable or an ideal choice as a building material

- PVC windows pose a threat to the health of the residents

- PVC is not fire resistant

- Europe has banned 3 chemicals used in making PVC windows

- PVC leads to the release of dangerous quantities of dioxin and other carcinogens

What makes uPVC the best choice?

Reason to

Choose | Replace | Suggest

01

uPVC products are highly durable, requiring minimal maintenance, and can maintain their appearance for decades, with a lifespan of over 50+ years, reducing environmental impact.

02

uPVC windows and doors feature a double-seal system combined with insulating glass, reducing noise levels by 30-40 dB, ensuring a quieter environment indoors.

03

Ideal for seaside locations and high-rise buildings, uPVC windows and doors maintain their strength through fully reinforced galvanized steel inner frames, offering resistance against heavy winds.

04

Insulated Glass Units in uPVC windows can be up to three times more effective than normal glass at maintaining cool temperatures within a building, leading to energy savings.

05

Unlike wooden counterparts, uPVC profiles remain free from termite infestation in all climates, ensuring longevity and structural integrity.

06

Multi-point high-security locks and fittings make uPVC products robust and secure for both residential and commercial use, with all components securely screwed into the steel core of the frames.

06

uPVC is self-extinguishing, preventing the spread of fire, thanks to the fire-retardant materials used in manufacturing, meeting DIN standards.

06

Environmentally friendly and 100% lead-free uPVC profiles meet the greenline norms of European countries, ensuring pollution resistance and eco-friendliness..

06

uPVC windows require minimal maintenance, eliminating the need for painting, solutions, or liquids for insect prevention, ensuring hassle-free upkeep for all seasons.